- Industry News

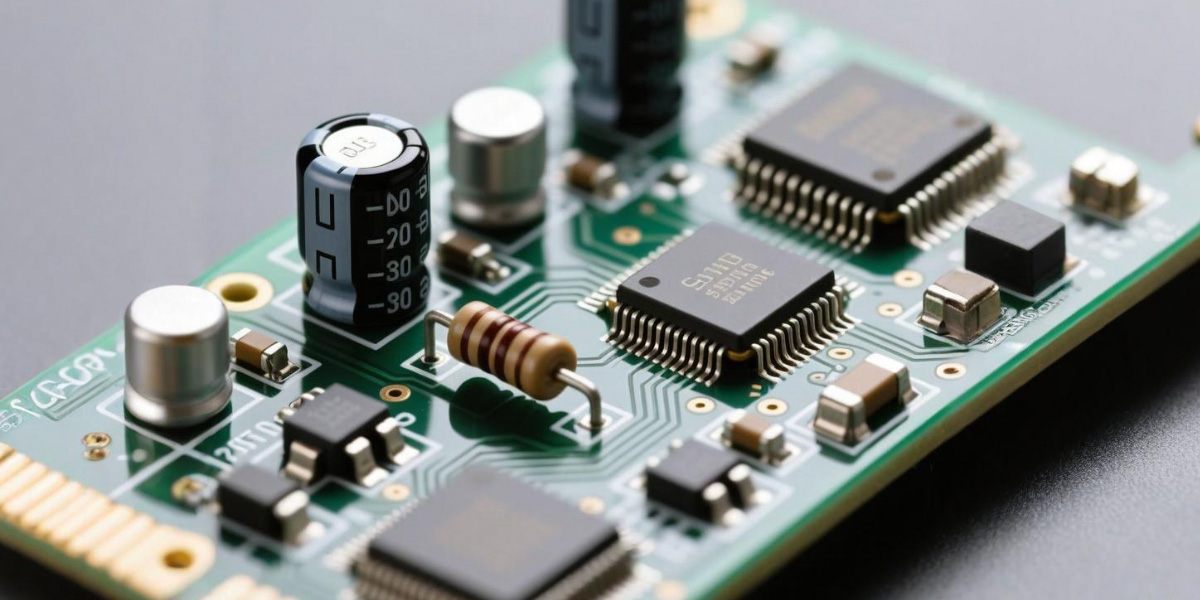

Electronic Component Parameter Guide: Understand Key Specs at a Glance

- By tian81259@gmail.com

If you design or purchase electronic assemblies, you live with component parameters every day – sometimes without realizing it. Resistance tolerance, capacitor ESR, diode reverse voltage, transistor junction temperature… these numbers on a datasheet directly decide whether a power supply runs cool for 5 years or fails in six months.

This guide walks you through the key parameters of common electronic components — resistors, capacitors, inductors, diodes, transistors, and ICs — and explains how to read them, what they mean in real circuits, and how they affect reliability. It also connects lab theory with factory practice, showing how mechanical handling and electronic component forming machines influence whether those parameters stay within spec in real production.

1. Why Component Parameters Matter More Than Ever

Modern electronics are more compact, hotter, and more tightly regulated than ever. A few reasons why parameters deserve serious attention:

- Higher power density in chargers, adapters, LED drivers, and EV-related systems means resistors and capacitors operate closer to their limits.

- Global compliance standards (IEC, IPC, UL, etc.) enforce creepage, clearance, and thermal limits that are directly tied to datasheet ratings.

- Cost pressure pushes teams to choose “just good enough” parts – which only works if you really understand the parameters and apply derating.

- Automated production means thousands of components are cut, bent, and formed every hour; any misuse can quietly shift parameters or increase failure risk.

Understanding parameters is no longer optional – it is a prerequisite for stable design, smooth certification, and low field-failure rates.

2. How to Read a Datasheet Without Getting Lost

Every manufacturer’s datasheet looks different, but most follow a similar structure. A practical way to read them is to scan in layers: overview first, then details.

- Start with the first page

Look at the part description, main features, typical applications, and a quick parametric summary. This tells you whether the part even fits your use case. - Check “Absolute Maximum Ratings”

Review the voltage, current, power, and temperature limits you must never exceed. These are hard boundaries, not recommended operating points. - Review “Recommended Operating Conditions”

This is the realistic range where the manufacturer expects proper performance and guaranteed specs. - Study “Electrical Characteristics”

This is the heart of the datasheet – parameters, test conditions, typical and min/max values. - Look at curves and graphs

See how parameters change with temperature, frequency, or load. Many “mystery failures” are simply parameters drifting outside what the designer expected. - Check package and mechanical data

Dimensions, lead pitch, coplanarity – critical for PCB layout, wave soldering, and for how leads are cut and formed on the production line.

Once you can navigate these sections, you can start to interpret the most important parameters by component type.

3. Key Parameters by Component Type

3.1 Resistors: More Than Just Ohms

Resistor selection often looks simple: pick the resistance and tolerance, then buy the cheapest option. In reality, technology (thick film, thin film, metal film, wirewound), power rating, and temperature behavior all influence accuracy, drift, and lifetime.

Typical resistor parameters:

| Parameter | Symbol | Typical Range | Why It Matters |

|---|---|---|---|

| Resistance | R | 1 Ω – MΩ ranges | Sets voltage/current levels (dividers, bias networks, current limiters). |

| Tolerance | ±% | ±0.1%, ±0.5%, ±1%, ±5% | Allowed deviation from nominal; critical in precision circuits. |

| Power Rating | P_rated | 1/16 W – 2 W (SMD/through-hole) | Max continuous power; exceeding it causes overheating and drift. |

| Temperature Coefficient | TCR | ±25 – ±200 ppm/°C | How resistance changes with temperature; key for long-term stability. |

| Max Working Voltage | U_max | 50 – 500 V (typical) | Upper voltage limit; exceeding it risks arcing or insulation breakdown. |

| Pulse / Surge Capability | — | Application-specific | Determines survival under inrush, surge, and pulse loads. |

In power electronics (e.g., SMPS feedback, current sensing), engineers typically:

- Derate power to about 50–60% of P_rated at worst-case ambient temperature.

- Use low-TCR, tight-tolerance resistors in precision feedback and sensing networks.

- Pay attention to surge/pulse ratings in inrush paths, bleeder networks, and snubbers.

3.2 Capacitors: Capacitance, Voltage, and ESR

Capacitors look simple on the PCB, but their behavior is complex. Ceramic, electrolytic, film, and polymer types all behave differently with temperature, DC bias, and frequency.

Typical capacitor parameters:

| Parameter | Symbol | Typical Range | Why It Matters |

|---|---|---|---|

| Capacitance | C | pF – mF | Energy storage, filtering strength, timing constants. |

| Voltage Rating | V_rated | 6.3 – 630 V (common ranges) | Max DC/RMS voltage; usually derated (often ≥ 2× application voltage). |

| Tolerance | ±% | ±5%, ±10%, ±20% | Important in timing and precision filter applications. |

| Dielectric / Series | — | X7R, X5R, C0G, electrolytic… | Defines stability vs. temperature, DC bias behavior, and losses. |

| Equivalent Series R | ESR | mΩ – Ω | Affects ripple current, heat, and control loop stability in power supplies. |

| Ripple Current Rating | I_ripple | Application-dependent | Max AC current without overheating. |

| Operating Temperature | T_op | −40 – 105/125 °C (typical) | Life expectancy falls rapidly near the upper limit. |

For high-reliability designs such as chargers, adapters, and LED drivers, common practices include:

- Derating voltage and ripple current based on vendor guidelines.

- Mixing capacitor types (ceramic + electrolytic + film) to balance ESR, lifetime, and cost.

- Checking DC bias and temperature effects using manufacturer tools or simulation data before finalizing the BOM.

3.3 Inductors: Inductance, Current, and Saturation

Inductors store energy in a magnetic field. In power electronics they set switching ripple, transient response, and efficiency.

Typical inductor parameters:

| Parameter | Symbol | Why It Matters |

|---|---|---|

| Inductance | L | Determines ripple current and energy storage; higher L lowers ripple. |

| Rated Current | I_rated | Current at which temperature rise reaches the specified limit. |

| Saturation Current | I_sat | Current where inductance drops significantly; exceeding it distorts waveforms. |

| DC Resistance | DCR | Defines copper losses (I²R) and impacts efficiency. |

| Self-Resonant Frequency | SRF | Frequency where behavior shifts from inductive to capacitive. |

For DC-DC converters you normally size L, I_sat, and DCR together with your switching frequency and ripple-current targets.

3.4 Diodes and Rectifiers: Voltage and Current Limits

In rectifiers, free-wheel diodes, and protection circuits, you typically focus on:

| Parameter | Symbol | Why It Matters |

|---|---|---|

| Repetitive Peak Reverse Voltage | V_RRM | Max reverse voltage; must exceed worst-case transients with safety margin. |

| Average Forward Current | I_F(AV) | Continuous current capability; derated with temperature. |

| Forward Voltage Drop | V_F | Conduction losses and thermal performance. |

| Reverse Recovery Time | t_rr | Critical in high-frequency switching to minimize losses and EMI. |

| Junction Temperature (max) | T_j(max) | Upper limit of safe operation; drives heatsink and layout requirements. |

Fast and ultra-fast diodes are used in high-frequency SMPS. Schottky diodes are common at lower voltages for their low forward drop and short recovery.

3.5 Transistors and Power Devices: Voltage, Current, and Thermal Limits

For BJTs, MOSFETs, IGBTs, and other power devices, datasheets usually emphasize:

- Voltage ratings (V_CE, V_DS, V_GS): must comfortably exceed worst-case line, load, and transient conditions.

- Current ratings (I_C, I_D): continuous and pulsed, with safe operating area (SOA) graphs.

- On-resistance / gain (R_DS(on), h_FE): define conduction losses and drive requirements.

- Thermal resistance (R_θJA, R_θJC): used to calculate junction temperature at a given load and ambient.

- Switching times (rise, fall, turn-on/off, gate charge): especially important in high-frequency SMPS and motor drives.

A sound design always ties these parameters back to ambient temperature, PCB copper area, airflow, and any attached heatsinks.

3.6 Integrated Circuits (ICs): Beyond Individual Parameters

IC datasheets are often much longer, but the same principles apply. Some of the most important IC-level parameters include:

- Supply voltage range and quiescent current (for efficiency and standby consumption).

- Input/output voltage range, common-mode range (for op-amps), logic thresholds (for digital ICs).

- Timing specifications (propagation delay, setup/hold times, switching frequency, jitter).

- Accuracy and drift (reference ICs, sensors, ADCs, comparators).

- Package thermal performance (maximum power dissipation, R_θJA).

Reading one good vendor design handbook on how to interpret these specs will significantly improve how you read IC datasheets from any supplier.

4. Safety-Related Parameters: Creepage, Clearance, and Temperature

Beyond individual components, system-level safety parameters are defined by standards such as IPC-2221 for PCB design and various IEC safety standards for end equipment.

Key concepts:

- Clearance

Shortest distance through air between two conductive parts. - Creepage

Distance along the PCB surface between conductors. - Temperature rise

Maximum allowed temperature at a component or trace under load.

These parameters connect directly to component ratings. If a resistor, capacitor, or MOSFET runs near its maximum temperature rating, or if the working voltage pushes creepage and clearance limits on the PCB, you may need to change the component, the layout, or the derating strategy.

Practical PCB design guides usually provide tables summarizing recommended creepage and clearance distances versus voltage and pollution degree. Combining those tables with component ratings is the foundation of safe, certifiable hardware.

5. From Parameters to Production: Why Lead Forming and Handling Matter

Even if your design is perfect on paper, production practices can quietly undermine performance:

- Excessive force when bending leads can crack internal structures, especially in ceramic capacitors or precision resistors.

- Inconsistent lead length or angle can create soldering defects and long-term mechanical stress on the PCB.

- Manual cutting and forming introduce variability that affects creepage, clearance, and coplanarity.

For this reason, many power-electronics, household appliance, and industrial-control manufacturers rely on automated electronic component forming machines (电子元件成型机) in their production lines. Modern resistor lead forming machines and capacitor lead forming machines can:

- Control lead length, angle, and spacing within tight tolerances, helping real assemblies match design values for creepage, clearance, and solder joint geometry.

- Apply controlled forming force to avoid cracking or micro-damage that could shift component characteristics over time.

- Support high-speed, high-volume lines for chargers, adapters, LED drivers, power modules, HVAC and home-appliance control boards, and automotive electronics.

When design teams and manufacturing engineers review a new product together, it is useful to consider early how leaded components will be processed on electronic component forming machines. That alignment reduces rework, improves first-pass yield, and makes it more likely that real-world parameter behavior matches the calculations made during design.

6. Practical Workflow: A 7-Step Checklist for Evaluating Any Component

To turn all of this into a repeatable design habit, you can use a simple checklist whenever you add or change a component in your design:

- Clarify the role

What does this component do in the circuit (sense, filter, store energy, protect, switch)? - Define electrical stress

Identify maximum voltage, current, power, frequency, and expected transients under worst-case conditions. - Read absolute maximum ratings

Make sure your worst-case stress never exceeds these limits. - Check key parameters

- Resistors: resistance, tolerance, power rating, TCR, pulse capability.

- Capacitors: capacitance, voltage rating, dielectric type, ESR, ripple current, lifetime.

- Inductors: inductance, I_rated, I_sat, DCR, SRF.

- Diodes/transistors: voltage and current ratings, forward drop, switching behavior, thermal limits.

- ICs: supply range, accuracy, timing, quiescent current, thermal data.

- Evaluate safety and derating

Apply derating rules and check PCB creepage/clearance against relevant standards (such as IPC-2221) for your voltage class and environment. - Plan for production

Confirm that lead pitch, package, and mechanical dimensions are compatible with your assembly line and with the electronic component forming machines used for cutting and bending leads. - Document decisions

Record why you chose this part, what margins you used, and which parameters are most critical. This documentation helps future redesigns, quality audits, and cost-down projects.

7. References and Further Reading

To go deeper into specific parameter topics, many engineers regularly consult:

- Integrated-circuit vendor handbooks on reading op-amp, regulator, and converter datasheets, interpreting thermal data, and applying derating.

- Capacitor selection guides from leading ceramic, electrolytic, and film manufacturers that explain dielectric behavior, DC bias effects, ripple current, and lifetime.

- Resistor application notes covering pulse load behavior, temperature coefficient, long-term stability, and failure modes.

- PCB design standards such as IPC-2221, together with application notes on creepage, clearance, and insulation coordination.

- Knowledge centers and technical blogs from major global distributors, with practical articles like “How to read datasheets”, “Choosing capacitors for power supplies”, and “Inductor selection for DC-DC converters”.

When you treat datasheets as the contract between your design and reality — and you align them with robust manufacturing practices and well-tuned electronic component forming machines on the factory floor — you greatly increase the chance that your products will meet specification not only in simulation, but after thousands of hours of real-world use.

Q1: What are the most important electronic component parameters in power electronics?

A1: In power electronics, the most critical parameters usually include voltage and current ratings, power dissipation, temperature limits, ESR for capacitors, RDS(on) for MOSFETs, and creepage and clearance distances on the PCB. These parameters determine efficiency, reliability and safety in real-world operation.

Q2: How do I read a datasheet if I am a beginner?

A2: Start with the first page summary to check if the part fits your application. Then review the absolute maximum ratings, recommended operating conditions and electrical characteristics. Finally, study the graphs to see how parameters change with temperature, frequency and load. Over time you will recognize common patterns across different manufacturers.

Q3: Why are creepage and clearance parameters so important?

A3: Creepage and clearance define the minimum safe distance between conductive parts on a PCB. If these distances are too small for the operating voltage and pollution level, your product may fail safety tests, experience arcing, or suffer from long-term insulation breakdown.

Q4: How can electronic component forming machines improve reliability?

A4: Electronic component forming machines control lead length, angle and spacing with consistent force. This reduces mechanical stress on components, improves solder joint quality and helps real assemblies meet the creepage, clearance and thermal assumptions used in the original design.

Q5: When should I derate electronic component parameters?

A5: You should derate parameters whenever your design operates near a component’s limits or in harsh conditions. Common practices include lowering the allowed power dissipation for resistors, using capacitors at 50–70% of their voltage rating, and adding thermal margin for semiconductors based on real measured temperatures.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei